Aeroscraft cargo airship contains built-in internal ballast control which allows VTOL and hover operation at max payload without the use of off-board ballasting, as well as off-loading stores while hovering.

Payload

Payload

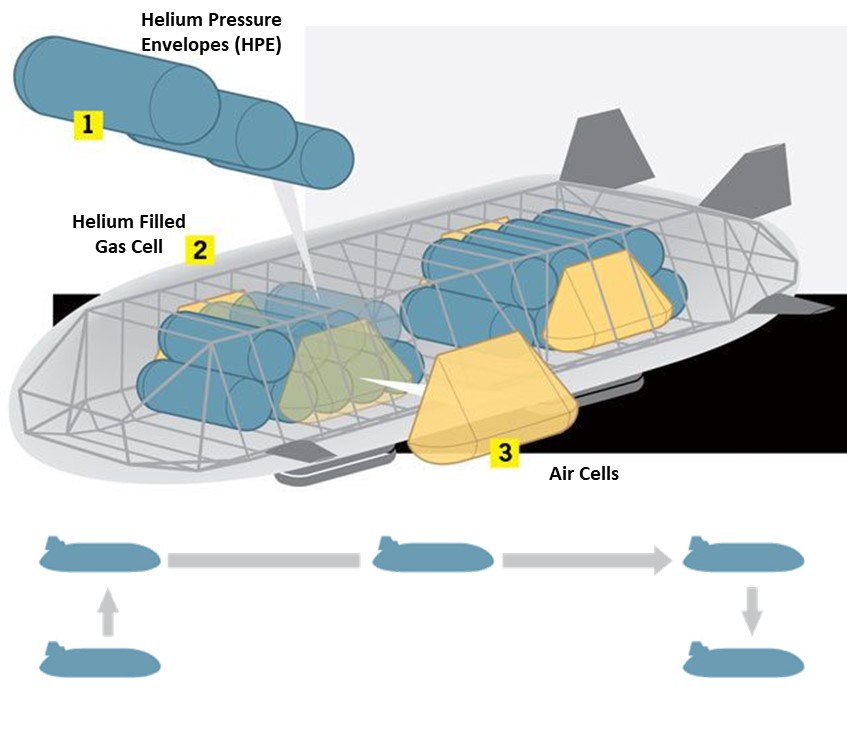

The COSH system compresses non-flammable helium into the helium pressure envelopes to allow the vehicle to manage buoyant lift similar to the submarine’s ballast management underwater. COSH allows the Aeroscraft to act as a “flying submarine.”

A scaled-down prototype of the 66-ton payload vehicle has been completed and fully demonstrated its functionality

The 266 ft (79 m) long Model ML806 ( 6-ton payload) full-scale prototype has been manufactured and tested under Project Pelican in partnership with NASA, DARPA, and DoD.

The test confirmed that technology is ready to move forward with the advancement of the commercial operational aeroscraft.

Aeros’ proof-of-design technology demonstrator can be scaled up to become a cargo airship capable of carrying 250 tons.

Modern airships have an envelope made from fabric and rely on helium pressure to retain their structural integrity. Malfunction of pressure management system or tear of envelope fabric can lead to catastrophic events.

The Aeroscraft has a rigid design and is not dependent on gas pressure made from advanced composite materials, a carbon-fiber geodesic space frame. reduction of the weight without the loss of strength; reduced manufacturing and operation cost, high damage tolerance, and drug reduction

The patented COSH system allows the Aeroscraft to compress inert helium for in-flight ballasting, which enables true vertical take-off and landing flight without external ballasts, used bother airships. By being able control the vehicle’s heaviness relative to the outside air, the Aeroscraft has eliminated the need for infrastructure and ground personnel from the equation, and opened a new area for cargo logistics, commercial and government transportation.

Fly-by-Touch flight controls, a high-performance multifunction display, camera system, avionics, and an advanced instrumentation package. The Augmented Pilot Vision System (APV) provides pilots with an enhanced visual field of view and zero visibility takeoff and landing capabilities. The cockpit design is an example of the innovative concepts and thinking that are being conceived by Aeros engineers.

The propulsion unit includes a propeller driven by an electrical motor and a hydrogen fuel cell (H2FC) to generate electricity for these motors. Fuel cell technology offers significant energy efficiency and decarbonization benefits. The H2FC is a type of electrochemical cell that generates electricity through an electrochemical reaction, they are a clean source of power. Because there are no moving parts, fuel cells are silent and highly reliable.

Proprietary cargo holding & deployment system that automates, weight-balances, and permits terrestrial or marine cargo deployment. No ground loading or unloading equipment is required at departure or landing points, enabling cargo pick-up, inflight sorting, and unloading. The internal sorting system allows any cargo unloaded at any time.

The Aeroscraft’s enormous cargo bay (ML866: 264,000 cub ft, ML868: 1,043,100 cub ft) with multifold unrestructured underneath cargo bay opening permit to transport and installation of large oversize equipment or low-density cargo, Freight Class 500 at full load, ISO containers via air including many cargos not heretofore transported by air avoid ports and terminal bottlenecks.

Replacing the more familiar landing gear found on airplanes, the Aeroscraft is equipped with ABLS that aid the vehicle’s unique functionality. This system assist in landing on unimproved surfaces, even water, and perform like friction reduction during taxing and provide powerful gripping-suction capabilities.

The Aeroscraft used a Fly-by-Light control system instead of a traditional Fly-by-Wire. A fiber-optic network handles all the data flowing through the massive ship, it offers a higher data transfer rate, immunity to electromagnetic interference, and significantly lighter weight.

Subscribe To Our Newsletter To Get All The Latest Updates